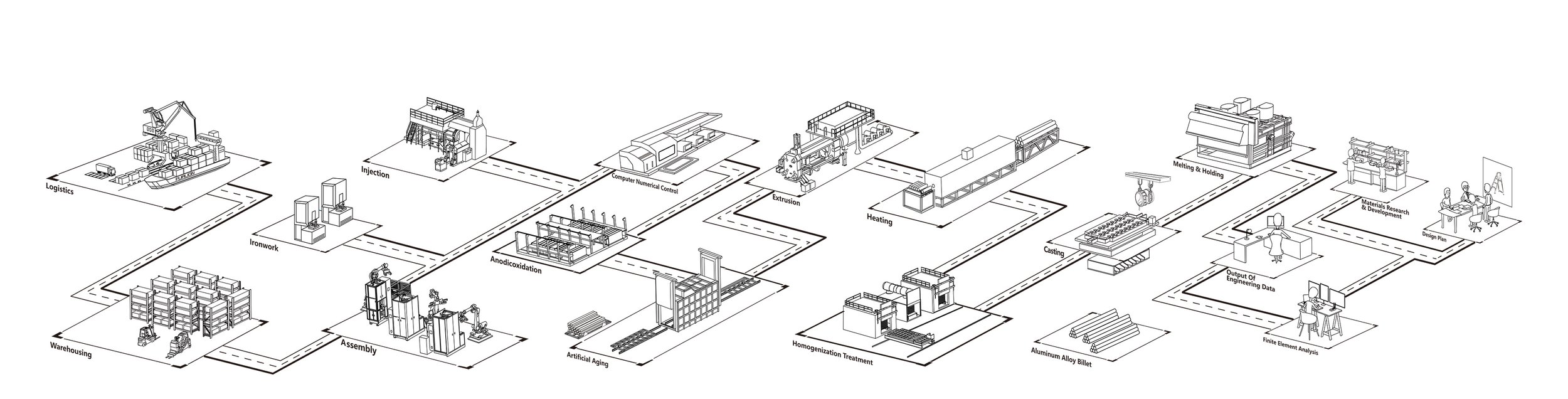

A Fully Vertical Integrated Inhouse Value Chain

-

![]()

Materials Research & Development

It is a discipline to study the relationship between material composition, structure, process, property and use performance, and to provide scientific basis for material design, manufacture, process optimisation and rational use.

-

![]()

Design Plan

According to the requirements of the design task, the designers use their own knowledge and experience to select reasonable technical systems and conceive the principle solution scheme to meet the design requirements.

-

![]()

Finite Element Analysis

Simulation of real physical systems (geometry and loading conditions) by means of mathematical approximations. By using simple but interacting elements (i.e. cells), it is possible to approximate a real system with a finite number of unknown quantities to an infinite number of unknown quantities.

-

![]()

Output Of Engineering Data

An input to the scope management programme that provides guidance on the collection of requirements, and the output of the project scope (i.e. the requirements document), which is the input to the prerequisites for the project work.

-

![]()

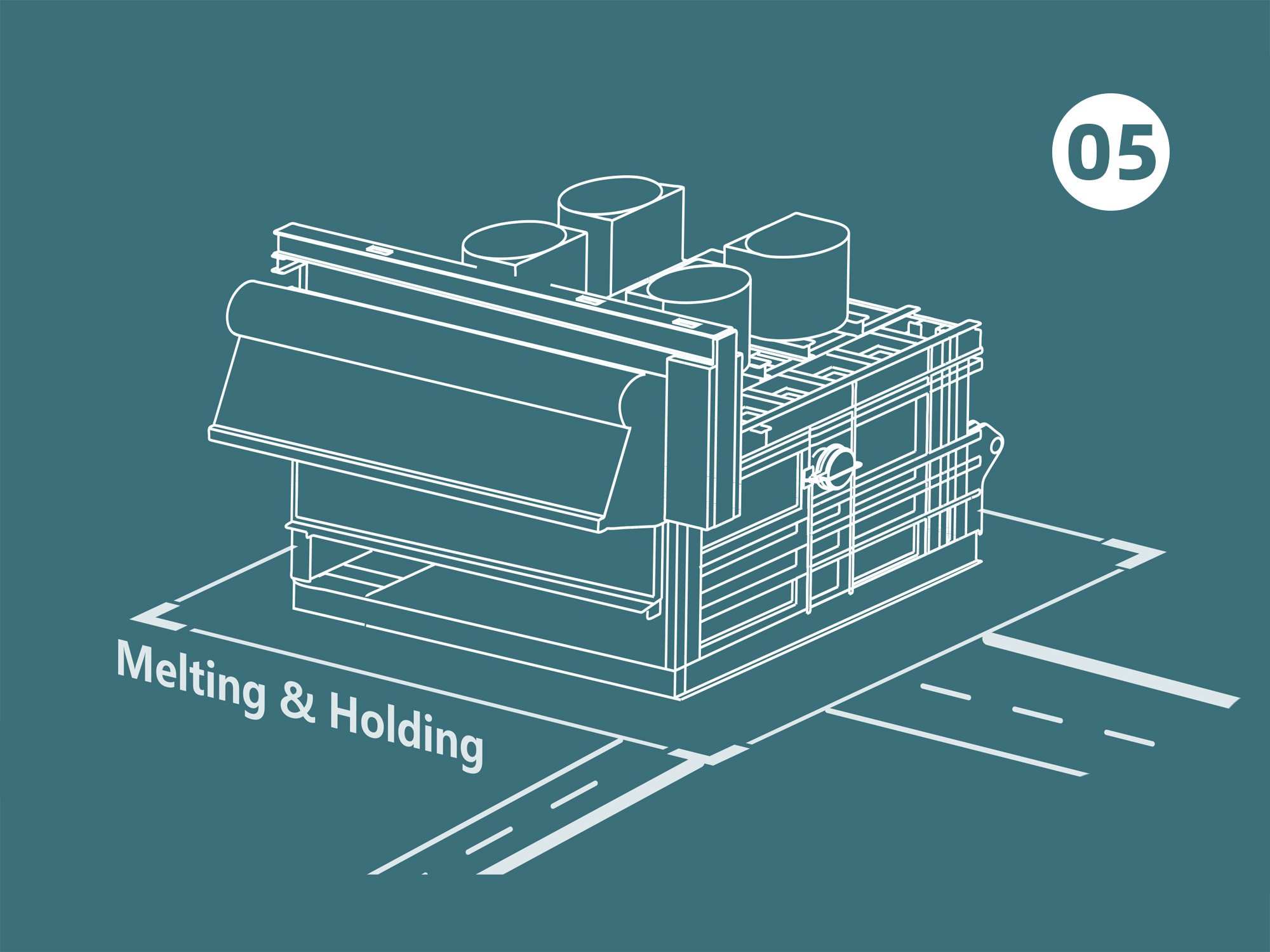

Melting & Holding

Melting is the process of heating and melting solid aluminium ingots, intermediate alloys and other auxiliary materials, so that the aluminium liquid undergoes certain physical and chemical changes under high temperature, and finally obtains the aluminium alloy melt with qualified and uniform composition and high purity.

-

![]()

Casting

Casting is the process of pouring the aluminium alloy melt that meets the casting requirements into the mould with a certain shape by means of a transfer tool, and obtaining a certain shape and size of ingot after cooling.

-

![]()

Homogenization Treatment

Homogenisation Treatment is the process of heating a cast bar and holding it at high temperature for a corresponding period of time to allow metal atoms to diffuse at high temperature, so that the unbalanced organisation of the cast bar tends to be uniformly distributed, the ingot's plasticity is improved, the resistance to deformation is reduced, and the organisation and properties of the product are improved.

-

![]()

Heating

Heat the raw material to a certain temperature.

-

![]()

Extrusion

Extrusion is a thermal process in which an external force is applied to a heated aluminium alloy bar inside an extrusion cylinder to cause it to flow out of a specific die hole, thus obtaining the desired cross-section shape and size.

-

![]()

Artificial Aging

Artificial aging is a treatment process in which an aluminium alloy that has undergone on-line solid solution treatment is heated to a suitable temperature above room temperature and kept there for a certain period of time to accelerate the precipitation of precipitated phases, resulting in a change in material properties.

-

![]()

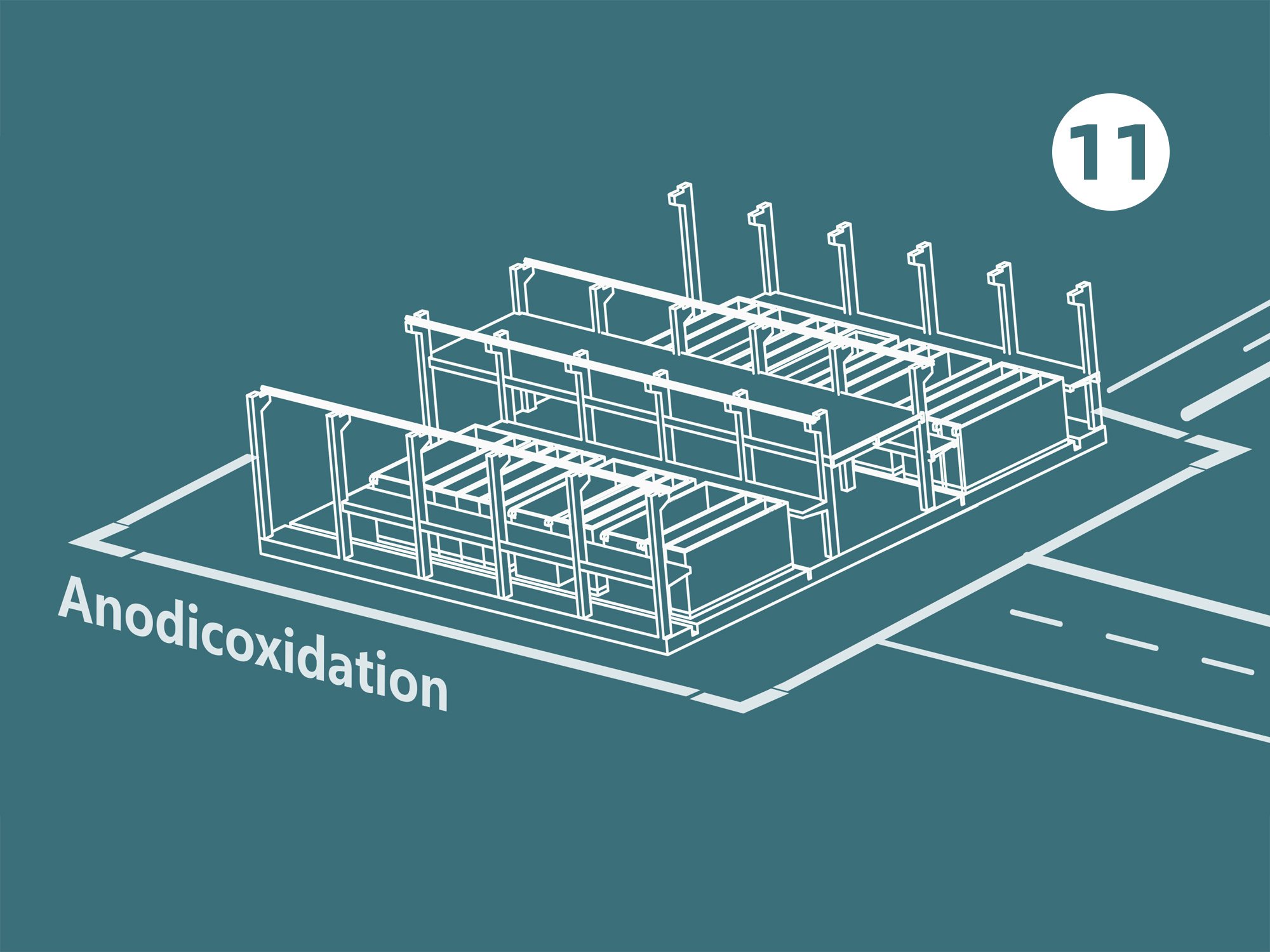

Anodicoxidation

Anodicoxidation of metals or alloys. The process by which aluminium and its alloys form an oxide film on the aluminium product (anode) as a result of an applied electric current in the presence of a suitable electrolyte and under specific process conditions. Anodic oxidation, if not specified, usually refers to sulphuric acid anodising.

-

![]()

Computer Numerical Control

An automated machine tool equipped with a programme control system. The control system is capable of logically processing a programme defined by control codes or other symbolic instructions, decoding it, expressing it as a coded number, and inputting it to the numerical control via an information carrier. After calculation and processing, the numerical control device sends out various control signals to control the action of the machine tool, and the parts are automatically processed according to the shapes and sizes required by the drawings.

-

![]()

Injection

The main moulding equipment for making plastic products of various shapes from thermoplastic or thermosetting materials by means of plastic moulds, which are realized by means of injection moulding machines and moulds.

-

![]()

Ironwork

Ironwork is made by shearing, folding, grooving, dropping, punching, stretching, extruding, etc. to produce hardware parts with high rigidity, stable high precision and reliable performance.

-

![]()

Assembly

Automated assembly line is generally an organic whole composed of conveying equipment and professional equipment, which is a highly automated assembly line based on electromechanics, information, image and network. Automated assembly line is the production equipment specialised in various assembly, testing, marking, packaging and other processes in the late stage of product manufacturing.

-

![]()

Warehousing

Warehousing refers to the use of warehouses for all kinds of materials and related facilities and equipment for the entry, storage, and exit activities. Modern warehousing refers to the traditional warehousing on the basis of increasing the library processing, sorting, library packaging and other links, warehousing is one of the important links of manufacturing and commodity circulation, but also an important part of logistics activities.

-

![]()

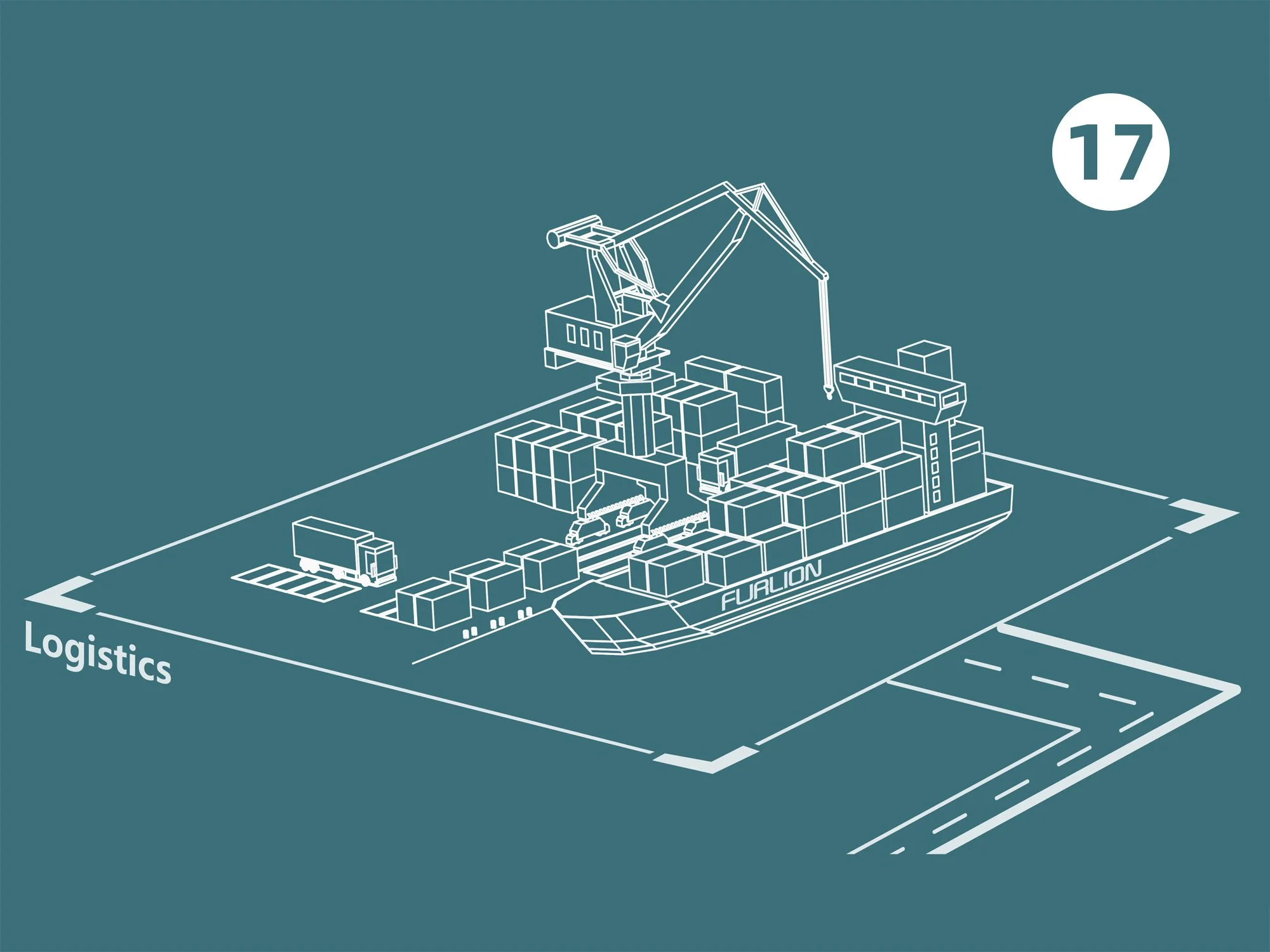

Logistics

Transportation, handling, storage, packaging, loading and unloading, circulation processing and logistics information processing and other basic functions of the activity, it is the flow of supply to the receiving place to meet the social needs of the activity, is a kind of economic activity.

Our Main Production Facilities & Equipment

-

Melting Equipment

-

Extrusion Press

-

Injection Machine

-

Automatic Welding

-

Automatic Riveting

-

Power coating line